Blog Entries

- 1/14/2019

- 10/15/2018

- 10/8/2018

- 10/1/2018

- 9/28/2018

- 9/25/2018

- 9/19/2018

- 9/18/2018

- 9/17/2018

- 9/12/2018

- 9/8/2018

- 9/7/2018

- 9/6/2018

- 9/5/2018

- 9/4/2018

- 9/1/2018

- 8/27/2018

- 8/23/2018

- 8/22/2018

- 8/16/2018

- 8/13/2018

- 8/8/2018

- 8/7/2018

- 8/6/2018

- 8/3/2018

- 8/2/2018

- 8/1/2018

- 7/31/2018

- 7/29/2018

- 7/28/2018

- 7/26/2018

- 7/25/2018

- 7/24/2018

- 7/23/2018

- 7/19/2018

- 7/18/2018

- 7/17/2018

- 7/16/2018

- 7/11/2018

- 7/10/2018

- 7/9/2018

- 7/8/2018

- 7/5/2018

- 5/20/2018

- 5/19/2018

- 5/17/2018

- 5/15/2018

- 5/14/2018

- 5/10/2018

- 5/9/2018

- 5/8/2018

- 3/22/2014

- 3/16/2014

- 2/22/2014

- 2/11/2014

- 2/7/2014

- 1/24/2014

- 1/17/2014

- 1/15/2014

- 1/12/2014

- 1/11/2014

- 1/6/2014

- 1/4/2014

- 1/1/2014

- 12/29/2013

- 5/7/2013

- 4/30/2013

- 4/25/2013

- 4/6/2013

- 4/4/2013

- 4/2/2013

- 4/1/2013

- 3/23/2013

- 3/19/2013

- 3/18/2013

- 3/14/2013

- 3/12/2013

- 3/11/2013

- 10/27/2010

- 10/11/2010

- 10/8/2010

- 10/5/2010

- 10/4/2010

- 9/29/2010

- 9/28/2010

- 9/26/2010

- 9/25/2010

- 9/21/2010

- 9/19/2010

- 9/18/2010

- 9/17/2010

- 9/16/2010

- 9/15/2010

- 9/14/2010

- 9/12/2010

- 9/11/2010

- 9/10/2010

- 9/9/2010

- 9/8/2010

- 9/7/2010

- 9/6/2010

- 9/4/2010

- 6/1/2009

- 5/31/2009

- 5/30/2009

- 5/7/2009

- 10/14/2008

- 10/10/2008

- 10/8/2008

- 9/18/2008

- 9/17/2008

- 6/9/2008

- 6/6/2008

- 6/5/2008

- 6/4/2008

- 6/3/2008

- 10/22/2007

- 10/19/2007

- 10/18/2007

This page is a place where I blog about electronics, robotics, and hardware hacking projects that I am working on at the time. Originally it was a robotics only page so the first entries start out talking about that project, but I eventually move away from talking strictly about robotics.

It's been a while since I've been posting a lot on YouTube. I wanted to create a list of Projects that I would like to work on in 2019:

- Getting the Arduino Mega Sensor Shield (currently have Version 2.0 but might get version 2.4) working on an AdaFruit GrandCentral with CircuitPython.

- The above board will host various sensors such as IR sensors, the Ultrasonic Ping Sensor, Light Level, and other similar type sensors.

- I would like to see an RA8875 LCD Panel Driver working in CiurcuitPython.

- Also I would like to see the DS3231 Clock Module working with CircuitPython.

- Another Project I attempted to work on last year included displaying characters on the HalloWing, but found out it is only capable of displaying images, so I would like to see a character library available.

I'm sure I will come up with more projects throughout the year, but these are projects that would be nice to work on in CircuitPython

I posted another Youtube Video at About unboxing my new camera for making better quality Youtube Videos. I've been working all weekend on the keypad driver for the Hackulator and am making good progress. If you would like more details and more frequent updates, you can check out My Hackaday.io project page. Since I have my Youtube channel going, updates on this blog are going to become much less frequent, so please subscribe to youtube. I may also post updates on twitter.

Big changes. After having a lot of clarity lately, I have decided to start my Youtube Channel going. I uploaded a video about restoring my Commodore 64 using a beer making enzyme buster which is meant for cleaning beer making supplies. Watch the video to see how well it worked. With all of the projects I have been working on and completing, I figured that this blog isn't really doing them justice and I will be moving to more of a project-oriented video format. While I admit cleaning a Commodore 64 isn't quite as exciting as some of the other projects I've been working on, it actually is pretty interesting to see the Commodore 64 being disassembled. I had recorded the raw footage and had only half edited the video. After resolving to get my Youtube channel going, I went ahead and finished the editing and uploaded it.

I still have some things to set up for the channel such as creating a thumbnail image for the video, but I at least came up with a good name for the channel. I'll be getting a better camera soon and will start recording some of the projects that I've worked on such as my Octo-Power Outlet which I need to disassemble to replace the relay module anyhow. I want to cover my 3D printer and I have a few other surprise projects that I haven't even mentioned on here yet. My plan is for this blog to start wrapping up and posts to become less frequent, so be sure to subscribe to my channel if you would like to keep up to date on my projects. I will probably be moving updates over to twitter as well as it is a convenient place to post quick updates. I have links to my social media channels at the bottom of my website.

This weekend, I finished writing the battery voltage monitor for the Hackulator. While doing research about how to display the battery voltage in the menu for the Raspberry Pi, I initially came across some information that developing plugins for LXPanel was the way to go. However, it seems the Raspberry Pi PIXEL environment is a highly customized version of LXDE and I was unable to find information of how to create a plugin. However, did notice that there is an existing plugin called "System Tray" which is part of the menu by default, so I looked in that direction and came across some python code that uses GTK+ to display an icon in that system tray. In fact the code I came across was for a battery monitor that read some system information about the battery and showed a representation there.

I was able to adapt this code to work with my existing python code that read the MCP3002 instead of the system and now it's working great. I just need to find the best way to run this on startup and it should be finished. My plan is to take a similar approach for the keypad, except I'll be doing that in C since I'm more comfortable doing low level stuff there. However, if it turns out rewriting my keypad driver in Python is easier, I'll go that route.

I finished installing the camera mounting adapter and put everything back together. Unfortunately, while looking through in different light, I noticed that the camera was set in a little too deeply. I made some adjustments to the design and made the camera inset about half a centimeter less, thickened the plate that it bolts onto, reprinted it, and reinstalled it and it's perfect now.

Another project that I started working on this weekend was hacking an HDMI switch. What I am trying to do is make it so that it can be controlled remotely with OpenHAB and I wrote a quick driver. After uploading it, it wasn't connecting to the MQTT server. I plan on getting it working on a NodeMCU first and then trying again. Basically, I have it connected to the output for the 4 LEDs to get which port is active and the button to trigger it to advance to the next one. My plan is for the software to figure out the current port and just advance it the appropriate number of times to get to the desired port.

Tonight I went to mount the camera in my adapter and it turns out it was just a bit too big. After a few more revisions, I printed another one out, put some double-sides foam tape so it would have a bit of a seal and tried it again. It went in tight and fits great. I tested it out and the angle looks so much better with a 15-degree tilt. Since it was dark out by the time I finished up and I don't work tomorrow, I decided I'll go ahead finish up taping everything together and putting the trunk back in order then. I may put the STL file for the camera mount up on thingiverse so that other people in the same situation can use it, though I doubt there will be that many of them.

One of the other project I was working on recently is making the blinds in my office motorized with a servo. I installed a kit that I purchased off the internet. Unfortunately it was made for some larger blinds than is standard around here. I was able to get the servo in and I lowered the blinds by 3/4 of an inch and it worked pretty good. Only issue is due to some small gears in the blinds, I wasn't getting the full range. So my solution was to order a 270-degree servo and swap that out. It came today and I replaced it and now it works great. However, due to the extra costs and the fact that it's not smooth, unless I sourced the parts for a bunch of kits myself, it wouldn't be worth it. cost-wise unless I come up with a simple modification to the servo that came with it and even then, it would still be cheaper to source the parts myself.

Also, I set up the Hackulator with a monitor, keyboard, and mouse and will work on the drivers this weekend.

I was looking into the LCD Controller Board I have. I received it a couple of weeks ago and it basically works and has the connectors for the LCD screen I have, but I didn't read the eBay ad closely enough and apparently the resolutions and screen ratios are programmed into the controller board and the one I bought had a 1280x800 resolution programmed into it so a black bar appeared on the right. This time I ordered from Aliexpress because the stated shipping times looked much faster (12-20 days as opposed to 24-59 days on eBay). I plan to use the board I have for now and will just swap it out when I get the new one. Also, it turns out that I will be getting another LCD that's 1280x800, but I'm not 100% sure it will be compatible as there are some EDID settings from my research that may not quite match up, but I can hope.

I got the Alexa Sample app going on the Raspberry Pi and it works great. I want to hook up a neopixel strip so it can show volume and if it's waiting on me to talk or if the microphone is off. I got a sample app with the neopixel running in python, but I need to get it running in C++. This is more a project I'm working on as time permits.

Now that the nozzle is replaced on my 3D printer, it's working so much better. I went to go print a mega-print, but after 5 hours, I noticed it had half lifted from the print bed. I decided to try a brim on my print to give it more surface area to stick and that did the trick. I was able to complete the power supply holder with socket and switch. I also printed off the camera mount for my car. I cleaned it up, but haven't had a chance to try installing it yet.

I had one of the relays on my OctoPower box go out. Actually, it's probably been defective for a while. Basically it won't turn on if most of the other relays are on, but it will work if it's turned on before the others. I ordered another 8-Relay board and will swap that out. If I have another relay stop functioning correctly, I'll migrate one of the good relays from the current board. Since I was only using 7 of the outlets, I migrated the other devices to working outlets and updated the configuration in OpenHab,

On the hackulator, I did some more research into the battery monitor and it looks like the correct approach is really to write my own LXPanel plugin. So since I am taking that approach for the keypad, I can learn how to do it and use that knowledge twice. I'm not sure if I can do it with python or if I'll have to rewrite the MCP3002 in C++ or if it can be done with either language.

Tonight I replaced my 3D Printer nozzle with a 0.4mm nozzle instead of the 0.3mm it had on there and the flow is so much better, so now it's back in operation. I also hooked up my Octo-Power Box and got that working through voice commands and I set up my windows computer to remote start up and shut down and enabled voice commands for that too. That one was harder because I could only find one example that was close, but I was able to get it figured out so that voice worked too. I got the LED strip control I built put up and functioning. I had to re-solder the ESP8266 chip because the flux was conducting and needed to be cleaned and I had a couple surface mount resistors that came loose on the strip that I fixed easily.

I finished up my Octo-Power Box and it works great. I made some more progress on the Hackulator towards getting it all set up and made a few decisions such as looking into creating some LXPanel plugins to deal with the battery level indicator and the Keypad Driver.

I received a bunch of the items I've been looking forward to and I also started organizing and prioritizing my projects and realized I had around 12 projects in the works of varying sizes. Over the weekend, I finished up the X-10 Controller Project I started last week including finishing touches on the source code, mounting it in a box, and writing up about the project. I also built a Sonoff Dual Power Outlet Box that I was able to load the Tasmota Firmware onto.

I also made some progress on the Hackulator and fixed the wiring. One of the wires had broken off the USB board. I fixed that and then while plugging the USB into the Raspberry Pi, that connector broke. I ended up redoing it with 26 gauge wire instead of 22 gauge, which was much too stiff and everything fit much nicer. I did some work on turning off the LCD screen when powering down, but don't have that working consistently. I came across an article that details how to do it the way I was actually planning on doing it, so I'll have a closer look at that later.

I worked on my Octo-Power Outlet Box with 8 relay controlled outlets and loaded Tasmota onto the NodeMCU and that actually worked pretty great, so I'll probably just stick with Tasmota for that purpose since it's more fully featured than some of the other firmware I've come across. I also worked on the wiring for the box and stripped and tinned all of the wires needed for the power wiring, which was quite a bit. Unfortunately, I cut my thumb pretty badly with a knife in the process, but I'll live. I found a nice case for the relay board, but when I went to 3D print it, I found that my nozzle was jammed and having difficulty extruding. I ordered some items so that I can replace me 0.3mm nozzle with a 0.4mm nozzle which will allow faster prints and less clogging, but also less fine detail. Since I plan to mostly print cases and not so much precision parts, I figured I can live with that trade off. I also need to work on re-leveling my printer bed and can do that while waiting for the parts to come in.

I also had the OLED display in my X-10 controller flake out, so I re-uploaded the firmware to be sure it was functioning and swapped out the display with my last spare, which the whole process only took me about 5-10 minutes to repair.

Monday, I received my other Light Switch and it installed very easily. After all the playing around with the X-10 devices, I decided to buy a CM15A off eBay or multiple reasons:

- It plugs right into the wall and can plug into the Pine64, so it is not dependent on Wireless

- It should be able to poll for the status of X-10 devices rather than blindly sending commands

- It works on all House Codes, so it isn't limited to only 16 devices, though that wasn't a deal breaker.

- There's already existing software to interface with this device (Mochad) and an existing binding in OpenHab2.

I got an AdaFruit Huzzah Feather because it can make use of a LiPo battery for reliability and wired up a couple harnesses, so the entire thing can be assembled without a breadboard. I should be getting a project box in a couple of days that I'll stick the circuitry into. I polished up the firmware and implemented the new commands so other people can put together a cheap and easy modern FireCracker controller if they happen to have a firecracker laying around or want to buy one to throw it together. However, even though everything says so online, the All Off Command just didn't seem to work. Everything else did. If you're interested, you can get the code from Github. I also wrote a fairly detailed Readme for how to get this up and running with OpenHAB.

It turns out the micro USB port on the Hackulator isn't working right, so I need to look into that, but it should be fairly simple as it's nothing more than a glorified micro usb extension cable. I will work on this soon. I spent all evening working on rewriting the firmware to be much nicer for public eyes, so I ran out of time to work on this tonight. Also, I started a project for this on Hackaday.io and uploaded a few pictures.

Tomorrow and the next day, I should be getting some stuff to build some OpenHAB friendly Smart Outlets to control even more devices. One of the limitation with the X10 devices is they are only designed for ungrounded devices, which can be a bit annoying. Also, I should be getting another smart dimmer switch identical to the last one I got and I plan to open it up and write some custom firmware so that it can work with OpenHAB and not some Chinese controlled server like they are now.

I preformed the electrical tests for the Hackulator again and they tested good. I also had to shave down the faux connector so that the battery panel laid flat. I also took a sharpie and colored any places that should be black. The calculator is looking really great and it's pretty much just software that I need to work on at this point.

I went ahead and connected the X10 FireCracker to the Wio Link since it is WiFi capable and I thought it would make a great board to control the FireCracker with. My only concern was that the Wio Link/ESP8266 uses 3.3V logic and since the FireCracker has an RF Transmitter, I wasn't sure if it would work properly at that level. According to the Data Sheet for the PIC 12C508A that is used on the FireCracker, it should function at 3.3V. I figured that I should probably set the 2 items fairly close just in case and after that the best thing to do at that point is to try. I went ahead and took apart a DB9 Serial Cable to use the connector on it since the 4 wires in the cable didn't have the proper connections.

I loaded the Arduino Library and after making some adjustments to the library due to the fact that it was written for a much older version of Arduino, it compiled just fine. I uploaded it to the Wio Link and the program worked great. I decided to keep the DB9 Connectors on the FireCracker in case I ever needed to replace that component since they are still available to purchase. This will make it much more modular and less work for me. I received a couple ESP8266 NodeMCU boards today that I had ordered. I hooked up the OLED I had bought for the function generator since I decided not to continue working any further on that project because it was more to scratch an itch than anything else. I attached the Firecracker to the NodeMCU and uploaded the code I had been working on and it worked great. I modified it so that it displays the command that it is sending along with the House Code and Device ID.

After that I spent some time writing some code that subscribes to my MQTT server, which is running on my Pine64 and listens for commands. If it gets a command, it decodes it, sends it to the FireCracker, which is received by the X10 Radio module which transmits it through the house wiring to the rest of the house. There's a lot of optimization that could happen with the Arduino code, but I wanted to write something that at least functioned. Later, I plan on designing and 3D print a simple box for the NodeMCU along with a cutout for the display, a hole for the USB Port, and a place to attach the serial port.

I also got a Smart light switch that I would like to get working with OpenHab. Currently it works with Smart Life, which from my research is really a rebranded Tuya. It looks like several people are trying to get this working, so at least I'm not alone. For now, it at least works with Alexa. As you can probably tell, I like challenges like this and tend to do pretty well with tackling them.

After that, I'll probably design and 3D print a box for the NodeMCU along with a cutout for the display, a hole for the USB Port, and a place to attach the serial port.

Tonight I almost completely finished assembling the Hackulator. I decided I was going to glue the rear cover on so I could cut more of the insides away because it was so tight. I ended up using hot glue to place things inside and had to make a few minor adjustments such as making wires longer or re-gluing parts in a slightly different place. I had accidentally pulled an SMD LED off with some hot glue and overheated it while trying to solder. I was able to put a different LED on in it's place, but it's red instead of blue. I still need to do some final checks to make sure everything still works electrically, but that will be tomorrow. I want to prepare to present it on Adafruit's Show n' Tell soon and I'm thinking either this week or next.

I discovered that the Wio Link (which I had bought off Kickstarter a couple years ago runs with an ESP8266 and I can program it in Arduino. That makes it so much more useful than I originally thought. I'm thinking about using it for my smart home project. I have 2 Wio Links and a load of sensors, so hopefully it will be useful. I was able to get an OLED LCD and strand of 30 NeoPixels successfully working by uploading sketches with the Arduino IDE. I also have a relay module that I'm pretty sure is just sending an on/off to the port.

I pulled out my X10 stuff because I got to thinking and did a search. It appears that some other people have already interfaced with the X10 FireCracker (the computer Interface), plus it's well documented, so I think that will make it much easier to make use of. I opened a radio receiver unit for X10 that was not responding to a remote. The insides had gotten food in them and corroded. I took some solder, flux, and wick and re-tinned the contacts as well as cleaned it up. After putting it back together it started working great.

So I worked on the software setup for the Hackulator so that I could perform some hardware testing. I had written a little document that outlined the steps of what I did, so I followed those and installed the battery monitor. When I ran it, I got a reading, but it appeared way off. Upon closer inspection, I had discovered that I soldered the 2 resistors in the wrong places. After swapping those I still wasn't getting a good voltage value. After looking at some data sheets, I discovered there's a few differences with the SPI communications between the MCP3008 and MCP3002. After making some adjustments (different config bits and doesn't require additional clock cycle) to the Python code, I got a fairly accurate reading that was off by just a hair, which works for me. The only big issue is that the program that displays the icon blacks out all of the screen except for the icon itself. I'll have to search for a different solution later, but we have a good circuit.

Next I tested the On button after shutting down the Pi and that was successful as well. After that I compiled my keypad program I wrote in C and pushed every button and it worked great. So that means my board design and soldering job was a success. The next steps are to continue with the assembly, which I've decided to just go with hot glue as that simplifies a lot of things and after that it will just be a matter of getting all of the various software components working.

Ok, it looks like my Smart Home project Version 2.0 is going to be a big focus here soon. This has really been in the planning for a long time. You might wonder why I say Version 2.0 and that's because back around 1996 or so, I had set up my home with all sorts of X10 devices. Most of them were the Radio Shack Plug n Power devices, but they were really just relabeled. I even had bought a kit from X10 that included a module to connect to my computer's serial port and control them. It was a pretty extensive setup and I had a lot of fun doing it. I still have the majority of those X10 devices stashed away in a box including the computer module.

When I bought my Pine64, I had ordered it off kickstarted with the OpenHab package. This means it came with a Z-Wave module as well as OpenHab installed on an SD card. I was under the impression that I would be able to access some UI on the LCD screen when I ordered it. However, I got the wrong box and the Z-Wave module didn't even fit on the Pine64 in that box. After watching some Youtube videos of somebody who has a setup very similar to what I've had in mind for a while, it gave me some direction.

Tonight I went ahead and got Armbian running on the Pine64 and configured the LCD and Touch. Then I installed OpenHab 2 in the background along with JVM as a dependency. I opened it up in a web browser and maximized it and I think the setup will work beautifully. Also, since I have the LCD box, the Z-Wave module fits inside. I would still like to add a Raspberry Pi to control my 3D Printer, but I will probably just use a real Raspberry Pi for that.

After I get OpenHab completely configured to my liking, I will integrate Alexa and my Apple Watch and other things. Although I was originally planning on hacking the Serial X10 module to control some X10 devices, I hear that it is very inefficient by today's standards and I would probably just be better off replacing wall switches and other things with more modern versions. There's still a chance I may try anyways just for the challenge, but that will be later down the road. The LCD Screen/Raspberry Pi project that I want to work like an echo show will end up being a big part of the controls for this project

I also decided to continue working on the Hackulator tonight and went ahead and soldered everything together. I still need to transfer some files onto the Raspberry Pi Zero W since I was using the Raspberry Pi 3 for Development and set up the Battery Monitoring Program and that will be part of the electrical testing which happens next. That's to ensure all connections are attached properly. Once I confirm that electrical testing is good, then remaining assembly will be done.

I received my Function Generator today and it works great. I discovered how to use the X-Y Timebase on my Oscilloscope to draw a circle using 2 Sine Wave Inputs. I made some other pretty shapes by adjusting the frequency. One cool thing I would like to try in the future is creating square waves that would initialize something like an LCD.

I also received the AIY Vision Kit and assembled it without a problem. I only had issues when trying to boot it up because it would go to a black screen and freeze. With a quick search, I found the trick was to add over_voltage=4 to the config file directly on the SD card immediately after flashing. After that it booted fine. The piezo buzzer wasn't working until after I ran a distribution upgrade. After that, it worked great.

I also received a MAX1000 FPGA board that I had forgotten to mention. It has some additional LEDs and an accelerometer on board, so I could use that as well. It only cost around $30, so I thought I would get it.

I did some more work area setup and put up a couple more shelves as well as cleared my desk off and placed the oscilloscope and function generator down where I can use them. I also cleared out a bunch of RC helicopter stuff from a parts storage container and I plan on moving all of my semiconductors there so that everything is spread out a little better.

Well, I still haven't had time to work on my projects, but I should very soon. My wife left this morning to Colorado to help her Mom for a couple of months and the reason I haven't been able to work on my projects is because I was helping with all of the packing. I'm going to PAX tomorrow, so I'll be busy all day, but I should be able to resume projects on Monday.

I took the opportunity to set up my work area a little better today. I still want to mount some shelves and set up another lamp or two, but I have much more desk space. While working on things, I had an idea for another project. It's something I've been thinking about for the past few days after seeing some projects on Youtube. I'm looking at running Alexa off the Raspberry Pi 3 that I have. I have a spare 16" LCD screen that I picked up a while back at Goodwill for $2.50. I ordered an LCD Controller board off eBar for $22.50, so the total cost is only $25 so far. I'm thinking several ideas with how to get it up and running including mounting it on the back of a piece of glass to make a Magic Mirror running Alexa, or I might set it up more like an Echo Show. It will probably take a couple weeks for that to arrive, so I have some time to think about it.

Earlier this week, I was the Adafruit Ask an Engineer Trivia Winner and I talked about my calculator project that I'm pretty close to finishing. I won a Google AIY Vision Kit and I'm hoping to be able to integrate that into the project with the LCD screen. I was really nervous talking to Ladyada because she's been one of my inspiration with getting back into electronics, but I think I did pretty well.

I received the LCD and added it to my function generator project and it worked great. Since this is more of an experimental learning project, I plan to added the interrupt based timing and display a little more stuff on the LCD and will consider it complete at that point.

I have some shipping updates. The function generator that I ordered and I think it will arrive early next week based on where it is now and the holiday coming up on Monday. I received the Playbox for my Pine64 which I had forgotten about and that went together beautifully. I still need to completely reload Armbian on it because of some space constraints when I tried on an 8GB card. This time I have a 32GB card inside.

It will still be another few days before I can work on my projects again. I ordered a SSD1306 OLED Module for about $8 so that I can display the settings for my function generator on the it. It works at 3.3V, has only 4 pins, and works with U8GLIB which should make adding it quite simple. Plus it's small, so it doesn't hog much room on the breadboard.

I learned that the Bus Pirate can be used as an AVR programmer, so if I make my own circuit with an AVR then I shouldn't need to buy a separate programmer for it. I updated the firmware on the BP to the latest community version. I also wrote functions for the waves to return a float between -1 and 1 which I can change the amplitude on and it's working great. Triangle wave was a little different than I thought because it is either rising or falling. I now have it providing around 6000 samples of data per cycle, but I think I can squeeze some more out of it if I am able to use an interrupt timer instead of a delay. I used a similar technique when I was developing the robot board that read PWM signals on 6 channels that I needed very tight timing on.

I haven't had much time to work on my projects this past week and probably won't for at least another 4 days. However, I did end up ordering a reasonably priced Arbitrary Waveform Generator for about $90 that seems to get good reviews on the internet, but it will take up to a month to arrive. So I may still try and build one with locally sourced parts that's reasonably priced.

I ordered and received an Arduino Due because I wanted to play around with the DACs on it. I bought a genuine one and it actually jumped up in price by about $10 just after I bought it. I ordered and received a 12-bit DAC off of Amazon for about $6 to play around with as well. I put together a simple circuit and uploaded a Function Generator Sketch that I found online, but it uses a table of values that are pre-calculated and the resolution is kind of poor. So it doesn't actually use a "function" to "generate" the signal. I'm rewriting the sketch so that it is calculated out. This is more of a proof-of-concept project than anything else and maybe I can produce a real function generator that people can use.

The existing sketch has one potentiometer to adjust the frequency and buttons to select between 4 different waves. Since mine will actually be generated, I'm adding an amplitude potentiometer as well. I ordered some breadboard mounting ones that should arrive in a couple of days along with some more breadboard. Most of my breadboard is old stuff from Radio Shack that has single bus lines along the top and bottom. Price has come way down too, so I got 3 long ones for about $10. I'll probably continue toying around with this small project for the next few days, but I don't expect to be able to do much else.

I also looked into the Dremel project and it definitely looks possible. I found a model on thingiverse to print off a battery casing along with instructions on how to properly trick the Dremel into working with an AC adapter with a resistor, so I have a couple options to try out.

I attempted to print the part again on my 3D printer, but it was not extruding properly and failed midway into the print. However, I printed off a nice little case for my Bus Pirate. I may end up redoing that one though. It was a bit thin for my taste and I have the OpenSCAD file, so thickening it shouldn't be a problem. Plus it's a relatively simple design.

I had another idea for a project. One of the things that annoys me about my dremel tool is that it takes like an hour to charge the battery and it runs out in about 5-10 minutes. I do like the option of having it be cordless though. So my thoughts were to get a larger capacity battery for it and modify the old battery so that it allows an AC adapter to plug into the end of it and be cordless. I believe I could take apart the battery, remove the cell, and replace the insides with a barrel connector. Another option would be to 3D print something that goes inside. I think there are a lot of possibilities and it would allow me to have the best of both worlds.

My oscilloscope came today. There were a number of options that I know used to come as trial functionality, but since last December they now come pre-enabled. One of the functions that was hackable was the ability to run the oscilloscope at 100MHz instead of 50MHz. I followed the hacking instructions for that one feature and it's now enabled. I also went and calibrated all 4 probes.

Now that I have a working oscilloscope, I've been toying with an idea for a new project. Of course I want to finish my calculator first, but like any good author who always keeps a collection of story ideas, I like to keep a collection of project ideas. Anyways, my idea is to build an affordable arbitrary waveform generator. I'm still learning about how they work and I know the key to them is to use a DAC (Digital to Analog Converter) along with mathematically calculated signals. For instance, Assuming an amplitude of 5 Volts, a DAC could output anything from 0 to 5 Volts depending on the digital value like say 0-255. For a Sine Wave, it could be as simple as a for loop from 0 to 359 degrees with the digital value being something like (int) Sin(X) * 255 with X being the degrees. and a Triangle Wave would be (int) X/360 * 255. and a square wave would be (int) Round(X/360) * 255. I was thinking of exploring something like the Arduino, Raspberry Pi, or Beagle Bone Black to start out with. Also, it may end up being a good FPGA project.

This weekend I worked some more on my 3D printer with trying to make some larger prints. I updated to the latest version of Marlin and increased some of the printing speeds. I tried out some larger prints, but it seems that 80 degrees celsius wasn't cutting it for the print bed. I was able to get it to 100 now that I have a thermistor right next to the heating plate. Also, the heating plate isn't perfectly flat anymore, so I took out the glass, cleaned it off, put a sheet of Kapton tape on it and clipped it on top of the heating plate, and re-leveled the bed.

After about 6 hours, I successfully printed off the tallest item I've ever printed off, but with a couple problems. First, the bed was just a bit too high and the printer and it hit its ceiling at the top of the print job and some of the layers separated. I increased the temperature of the hot end to deal with the separating layers and tightened the bed leveling screws and re-leveled the bed to deal with the height issue and will give it another try tomorrow. I have a feeling I'll have better luck.

Instead of using my Raspberry Pi 3 for the 3D printer, I decided to use a Pine A64+ that I got off Kickstarter a while back since I already have a nice 7" LCD panel with it. Then I can use it for web-based printing as well as having a nice screen to control the print job. I ordered an injection-molded case for it so that I can have it in the enclosure. When I originally got it, I got a non-LCD case and added the LCD as an afterthought. I went ahead and installed Armbian since it works with the LCD and started setting up the various pieces of software to control the 3D printing including OctoPrint and PrintRun. Unfortunately after spending several hours installing dependencies, I ran out of space on the SD card, so I have to start over with a larger one. :(

I went and ordered a Rigol DS1054Z digital oscilloscope because I had sold my bulky analog one a couple years ago and the cheap oscilloscope kits I put together just didn't seem to cut it and I need this tool to push forward with my inventing.

I received the FPGA in the mail today, but I won't be able to get to that at this time. It will be in one of my upcoming projects.

The circuit boards came today. I went and soldered the components on the board and spent a bunch of time carving up the insides of the calculator (plastic removal). I still need to figure out where to solder the switch for the PowerBoost and and then it will just be figuring out where to mount stuff. I will probably be using a combination of superglue, hot glue, and possibly making something on the 3D printer.

Since I now have my 3D printer working, I decided to finish designing the camera adapter for my car. Unfortunately it's getting late, so I will need to wait for another day to actually print it off. It's very possible that I'll need to print it off multiple times while making adjustments in between, but that's the nature of prototyping. Fortunately I made it quite easy to make any adjustments just by changing a few parameters. After I get it all worked out, I may throw it up on Thingiverse in case somebody else with a similar car runs into the same issue.

While I was looking back at some older entries, I realized that I forgot to mention that I did end up replacing the stepper motor for the X-Axis shortly after that post.

Oh, and the circuit boards for the calculator are finished and should arrive her in a couple days. Then I can finish up the hardware part on that project.

So far it's looking like all the conditions I need to meet to get the voltage checker implemented are coming along nicely. I have the board being fabricated and already have all of the parts in hand. I breadboarded the circuits and they are all functioning nicely and the driver is coming along pretty well.

One thing I'm looking at exploring in the near future is FPGAs because with the price coming down, I feel they are going to start becoming more popular soon. I used to just love designing logic using gates when I was a teenager and in fact created a programmable robotic arm based on an EEPROM to store the data and TTL gates. It probably had about 25 chips on the board including LED display drivers and such. I have disassembled it since then because my skills have improved a lot, but I do still have some pictures of it. I mention this because I may start a project using one if I think of a great use such as building one of my old circuits I designed with many gates, but never got around to making.

I decided to give my 3D printer another try. I started by literally cleaning off the dust and replacing the heated bed screws with some screw knobs I got off Amazon that were much easier to adjust. This had been one of my annoyances with the printer since the beginning. I then leveled the bed, but realized I shouldn't have done it while it was hot because the screws got hot too, so I used some pliers and it was pretty easy.. After that I tried a print, but no luck. After some more time uninstalling software from the computer because it was so slow, I found the culprit to be Synergy. I'm not sure which version it was because I purchased the newer one, but it's possible I never updated it.

I installed Ultimaker Cura and while trying to copy some settings from slic3r, I noticed it was set to 3mm filament which would cause under-extrusion. I flipped it back to 1.75 and gave it another go and this time just a little too much extrusion. I can work with that. I measured and adjusted the extrusion steps in the firmware and tried again and it turned out great. It actually makes me a little teary because I was really getting to the point where I was really feeling limited by not having a working 3D printer and I could tell it was so close to being in my grasp.

On a similar note, it appears an updated version of the marlin firmware was released about a week ago, so I'll have to compare settings when I have a good hour and plug them in and update it.

Tonight I hooked up the shift register to an LED bar graph and wrote a little demo program and some utility functions in C to animate the LEDs. It turns out WiringPi has a library for the 74HC595 which makes things very easy. After getting this functioning, I don't think there will be any problems with the board design, so I feel pretty good about it. I also wrote some initialization code for the columns. Oh, the only other thing I was considering is writing it in Python, and at this point the only reason I would do that is if I can interact with the Linux UI and display an icon much more easily than with C so I can display if the keypad is in alpha mode or second mode.

I'm so awful. I revised the design again, so I cancelled my order, uploaded the new design, chose the Super Swift service which takes up to 5 days instead of 12, but doubles the cost. and resubmitted it Also, I went with free shipping because I found they were actually pretty close to where I live and the shipping time would be very fast anyways. It has already gone into production now, so there won't be any more changes, but I'm actually pretty happy with how it ended up. If there turns out to be a major design flaw, at least I know it will only cost me $7.30 and a week of waiting.

On a different note, I discovered that my local library offers free access to Lynda.com and they have a great course on debugging 3D Printer issues and one of the things they mentioned is trying out some different software (many of which I didn't realize was available).. Also, a possibility is that my extruder motor doesn't have enough power and it's under-extruding as a result. That's probably the first thing I'll try the next time I fire up the printer.

Also, another fun project in the future may be to hook up my Raspberry Pi to the 3D printer and install OctoPrint on it and then I can print over the network from other computers. I would want to get it printing much more consistently first though.

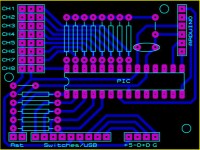

I went ahead and designed a board that is only 1 inch by 3/4 of an inch which I'm pretty sure will be able to fit. By making it so small, I was able to get the cost down to $3.65 for 3 boards and I had the option of free shipping. I opted for priority mail shipping to speed it up by up to 3 days. If anybody is interested in the design, it's available here.

I thought that when I connected the battery backwards to the PowerBoost 1000, I had ruined it so I ordered a new one. It turns out I just didn't wait long enough. Oh well, that can either go towards a different project or a second calculator. It's looking like it may not be until closer to the end of the month that I will have the basics completed. I'll continue working on the software parts of the project. By the time that the circuit board and parts arrive, it should be ready to assemble. Until then, I plan on cutting out a rectangle of circuit board to use as a placeholder.

Yesterday I didn't get a whole lot done. I mostly worked on some of the driver code and changing it from reading 4 inputs to more of a matrix.

Today I hooked up the MCP3008 and enabled the auxiliary SPI and it's working great. I found some software called GBZBatteryMonitor which is really just a stripped down version of PiCheckVoltage that's a little newer. I updated the MCP3008.py file with the correct pins and it worked well. It turns out when I swapped connectors for the battery, the new connector had the wires opposite of the one that came with the battery. So swapping connectors as well as wires resulted in the battery being connected backwards. I went ahead and fixed that. I also updated the python code that monitors the battery to use the second SPI port as well as making it so I can disable the status LEDs by setting them to 0 since that was a couple GPIOs that I wasn't planning on using.

So it looks like the piece of the puzzle that I thought was most unlikely to work is working. However, since there is a voltage divider going across the battery, my concern was that even with the power off, it will still continue to draw power from the battery, possibly causing it to go too low to charge. However, after doing the calculations, it should only yield a 0.54ma draw which very is negligible. Also, for the main circuit, since it only uses 1 ADC channel, I can get away with a MCP3002 which only has 8 pins. The next piece is to hook up the shift register to the keypad and make it so my driver works with that.

I ran into another issue with trying to get the MCP3008 chip working. It uses SPI and apparently the Raspberry Pi only has to Chip Selects available for its use on the main SPI. Both of these are in use by the display and touchscreen which are higher priority than a battery level check. Now there is an auxiliary SPI as well, but that would end up taking 4 pins as opposed to the one or two pins I was planning on using because I have to use a different set of MISO, MOSI, and Clock pins as well. In order to do that, this means I will need 4 things to be in place:

- PiCheckVoltage will need to run fine over the auxiliary SPI

- I will need to create a shift register circuit for the keypad

- The circuit that houses both the MCP3008 and 74HC595 (two separate circuits using through-hole chips) will need to be able to fit in the case

- I will need to write a custom driver rather than use a device tree overlay

If any of those 4 things doesn't work, then the voltage check will need to be scrapped. If it's only the circuit fit that's a problem and it's really close, I may be able to design an SMD circuit that fits. Also, I'm not sure if I'll use proto-board or just use OSH Park to make the board even if it fits fine, That's mostly a time vs space issue since I would need to design the board and then it's a 12 day turnaround, so that could easily take 3 weeks total.

I was able to sort of get the device tree overlay working. Some of the buttons responded, but it also seemed to think there was other buttons being pressed. I think I will leave the overlay file as it is for now and start focusing on a custom driver in c because I think I may need more flexibility than the overlay can give me. I am aware that you can do alternate key maps so that if the alpha button we held, then the alpha keys would function and same with the 2nd key. However, I'd rather they work more like the original calculator.

Ok, so I ended up getting the new calculator in the mail as well as some as the Raspberry Pi 3 B+ yesterday. However, I had a delayed package as well as a couple that were delivered to the apartment office right before it closed, so I had to wait until they opened today to pick them up. So now I also have a circuit board holder, a replacement magnifying glass (like the one I used to examine the circuit board traces), the MCP3008, and a raspberry pi cobbler. I ended up giving my Raspberry Pi 2 to my son because he was excited to get his hands on a Raspberry Pi. Also, I wasn't sure if I would need a power switch, so I got one of those in one of my orders. However, it's looking like it won't be necessary.

I took apart the new calculator and enlarged the window for the LCD using a combination of a Dremel tool, an X-Acto knife, and a file and it turned out pretty good. I hot-glued the LCD in place, kept the keys from my previous TI-83 and started carving up the insides of the calculator for the external ports. I also cut a sheet of Kapton tape to the size of the circuit board that I had from my 3D printer supplies so that I could set boards right on top of the existing board. I wanted to free up an SD Card for my son, so I ended up putting a 16GB card inside the calculator and setting it up just to make sure my process was easily duplicatable. I still need to set up bluetooth again, but I know I can do it for sure now.

I'm considering building a second calculator after my first because a lot of the research and software writing will be done with my first one, so it will be much easier. Besides, I already have much of the stuff needed to set up a second one. I would need a couple of displays, a PowerBoost 1000C, another battery, an HDMI extender, and another USB port (unless I just use that extra one I have). I guess I didn't realize how much stuff I actually needed, but I'll have to think about it.

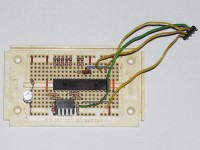

Since I don't want to solder a header onto my Raspberry Pi Zero, I went ahead and attached the cobbler to the Raspberry Pi 3 and hooked that into a breadboard. I put a little solder on each of the keypad wires and attached them into the breadboard. I went and wrote a good chunk of a device tree overlay file and compiled it, but unfortunately it didn't actually function on my first attempt. I unhooked it and manually tested every key with a multimeter and it tested fine, so I'm not quite sure of the issue yet. Most likely it's something in the device tree file that's backwards or missing. I noticed some artifacts on boot up if I have the keypad connected. Tomorrow, I'll get a T-cobbler and then I won't need to route the wires around the ribbon cable, so that will be nice. Also, as a test, I hooked up the On button and wrote a script to shut it off if I hold the button for 2 seconds and that works beautifully.

Today I got Bluetooth audio working. I just followed this guide and aside from a misspelling or two, it went pretty smoothly. I wasn't able to get it to play over command line using SSH, but it did play after I installed VLC and double-clicked the MP3 file, which is good enough for me.

A while back, I had discovered that you could download Lynda.com videos with youtube-dl, which placed stuff unsorted. I created an AppleScript script that would go the the Lynda website, get the list of files in the course and sort and rename all of the files accordingly. Over time, I got it working 100% perfectly. It was quite elegant in that it used jQuery that was loaded as part of their webpage to do a log of the heavy lifting. Also, I set a folder label to a color based on the course difficulty. I ended up downloading a bunch of courses from a trial.

So I went to load some files into VLC and it was sorting them wrong and I realized a playlist was just what I needed. Just for fun, I decided to write another AppleScript that recursively goes through each folder and checks if that label is set to determine if it's a course folder or a sorting folder. I could have also checked the name as well since they are prefixed, but this worked fine. So if it was a course folder, it would create an M3U file and sort the list by a numeric index that I prefixed to each file and folder. The hardest part was coming up with a way where 2 was sorted before 10 and so on. There were other scripts out there that created M3U files, but as far as I could find, mine was the only one to include the running time of each video file. Anyways, I finished the script and it worked beautifully. The next step would be to integrate it into the main sorting script, which would be much easier than the way I just did it.

Hopefully I'll do a bunch more calculator stuff tomorrow since that's when a bunch of parts orders are coming.

Don't you just love breakthroughs? I was looking at the Network mapping data I had and swapped some columns and realized that it is in fact a grid of 7x8 (at least electrically) plus the on button. It's just not arranged physically in the same grid that it is electrically, but it still the same. That means I have the option of using the GPIO-Matrix Device Tree Overlay like I originally wanted.

I received the second USB port and have decided to go with the Adafruit one. The contacts are better and I think the shape works better, but in all honesty, I think either would have worked out just fine.

One of the things I realized is there isn't a good way to check the battery level with my current design. I found a project that allows you to check this, so I ordered an MCP3008 A/D converter that I'll see if I can connect into my project. It really depends on whether I will have room in the calculator case.

I looked at the spreadsheet once again and with removing the audio board, it looks like I'll now have just enough pins because I was planning on using one for either the low battery output from the PowerBoost or the MCP3008 chip. In the event I don't have enough pins for my needs, I happen to have a 74HV595 shift register that I could hook up for checking the keypad that would free up 4 or 5 pins depending on how I decide to connect it. Space is the main issue and I don't believe I'll need to use it since the MCP3008 communicates via SPI and I only need 1 extra pin for the Chip Select. My main concern on that is the Display uses SPI and I don't want there to be any conflict and that will require further investigation.

I found a great page here about how to write something in C that would be a great base point. If I run it in the background as a service or a daemon just like FBCP, then I think that will work fine. I'm also thinking about reading in a config file or something so that I can make the keyboard function different depending on the mode. I went ahead and set up SSH and got it to compile an example so that I can modify it from there.

I'm kind of getting anxious to put everything in the calculator case soon as I feel the hardware part of this project is coming to a finale and then it will just be software. Part of the reason is because I've already had a couple wires break on me from moving it around too much. I just reattached them, but I'd rather just have everything in the case. With the way I am going to set this up, unless I need to remove the SD card to burn a new image, there's no good reason to open up the case. I'm thinking I should be able to finish the base part of the project up by mid-August and then I can add emulators, expand the keypad driver, play with power options, and set up the environment to exactly how I want it.

I received one of the USB ports today and after playing around with some different possibilities, I think I will end up placing the HDMI port at the top and the USB port on the bottom. Once I get the new case, I will be removing less of the plastic innards, so that some of the plastic I shaved away will be able to support the ports better.

One other quick thing I came across and tested is that Pin 5 works as a wake button which is great news. There's nothing to add to that and I can make off behave by turning off the LCD and shutting down or perhaps I can make the LCD contrast off work so that if it's powered off in the menu.

I was out of town for most of the weekend, so I wasn't able to get much done. I worked on getting bluetooth audio working and so far that has been a bit of a challenge, but still appears to be within the realm of possibility. On the presumption that I'll get it working, I have been looking at some alternate layouts inside the calculator. Because of leaving out the audio board, I decided that I could probably now fit a USB port that will go directly to the raspberry pi onto the calculator, but I haven't decided if the HDMI port will be where the audio port was or if that's where I'll place the USB port. I went ahead and ordered a couple of micro usb breakout boards to use for the port that are slightly different sizes because I'm not sure which will end up working best.

There was an adhesive on the board from where the LCD ribbon cable was attached. I didn't have any Goo-Gone, so after looking through what I did have, I ended up using some acetone since the only think I know it to dissolve is ABS and just to be sure it didn't have any ill-effects on the circuit board, I tested it on the TI-86 board and it was fine. By the way, I do know that one thing you don't want to use on circuit boards is ammonia because it will dissolve the green solder mask on many boards. Anyways, I tried in on the TI-83 board and it removed the adhesive just like I hoped. It also cleaned the board really well and it looks great.

Next, I finished mapping out the wires to all of the solder points where I was attaching wires into vias. I ended up taking a 25-pin computer cable and using wire from that so that it would all be consistent gauge, yet different colors. It took me about an hour to solder all the wires in place while taking care to not have any solder gaps. I placed all of the calculator keys back into their appropriate places (they had fallen out previously and I put them into a ziplock) and screwed the circuit board back on.

The next steps will be to solder all of the other wires to the Raspberry Pi and then to star writing some kind of driver for it. Hopefully it will end up being easier than it seems, but I'll see. I think I came across something I can use as a starting point and then I'll flesh it all out. Also, I need to test that there were no shorts in the soldering job and I'll do that shortly before soldering the wires to the Raspberry Pi. Another small issue I need to contend with is all of the wires ended up right below where I was planning on putting the Raspberry Pi. That may not end up being a big deal though.

This is just a short blog entry as I didn't have much time to work on my research. I now have the display working 100%. I got a little impatient and started digging in a little deeper myself. In the end I added spi_bcm2835 into /etc/modules to force SPI to start first and that fixed the issue. I posted my fix on the adafruit github for that issue, so hopefully that will help some other people out.

Another thing I realized that would make some more pins available is that I could just use Bluetooth Headphones. Then I could have my adjustable backlight pin back. I went ahead and ordered a broken TI-83 off eBay for $8 including shipping so that I won’t have the hole that I made for the audio port anymore.

I went ahead and mapped out the circuit board today. It wasn't exactly the rows and columns that I was hoping for, but rather networks of circuitry. I counted 15 distinct networks plus the on button was separate. When I mapped them out in a spreadsheet, the bottom 8 rows are definitely in a matrix as expected. However, for the top 2 rows and the arrow keys, they use some of the row networks as columns and that's why I decided to map it out as networks (a term I took from Eagle regarding a series of connections all electrically attached) rather than rows and columns.

So what does this mean? Probably that I will have to come up with my own solution for scanning all of the keys. The problem is that some of the pins will need to switch between being inputs to outputs and vice versa which I don't think will be a problem on the Raspberry Pi. Also, I've never written a driver before and not for linux and this is the first intensive thing I've done with the Raspberry Pi. However, I knew going in that this would probably be the hardest piece. and this is kind of what I was initially expecting to do.

So, this means I will need 16 GPIO pins for the keypad, which I think I can manage if I don't use the backlight. I measured the resistance of the buttons to be no more than 100 ohms and with the way the contact is, it will be probably closer to about 25 ohms. The next step will be researching what is involved in coming up with a software solution to scan the keys and are there any limitation that I should look out for. Also, I may need to come up with some kind of serial shifter or multiplexer circuitry so that I don't need to use as many pins if that's even possible with the way this thing is laid out.

I feel like I'm very close. To start out, I found an alternative FBCP driver for the hardware combination I'm attempting to get working available at https://github.com/juj/fbcp-ili9341. I went through the initial build procedure and it seems to be working with a few exceptions:

- It is displaying a bunch of numbers on the screen which should help with tuning it

- The touchscreen isn't working and this may be a deal killer/li>

- It appears to be choppy, but I need to go through the fine tuning process

After looking in the documentation, it explicitly says touchscreen will not work, but one may be able to get it working if they took a stab at it. After that, I switched back to the Adafruit FBCP. I found that if I run FBCP at the command line after booting it, it seems to work just fine with touch and everything. I tried placing it in the /etc/rc.local file, and it worked for a second, but then another copy started up and it stopped working. After running grep to search for fbcp, I found a service used to start it up. When I type sudo systemctl restart fbcp, it starts right up. I looked to see if anybody else was having the same issue and I found an open issue here which describes my symptoms perfectly. Just after posting a comment on it, it was assigned to somebody to fix, so I'm hopeful that all I need to do is wait for that.

Now as for the keyboard., I found an article that describes how this can be accomplished with setting up a GPIO Matrix Device Tree Overlay and a couple other components. I also came across a couple things that briefly mentioned using diodes to make it so key presses can't be mis-detected. I'll have to do some research on that.

I started mapping out the circuit board for the keypad by taking a picture and importing it into photoshop, but unfortunately I ran into an issue. The circuit board from the TI-86 is so corroded that some of the traces are completely dissolved. That's on top of the complexities of it that it isn't in a perfect matrix. At this point I have the option of repairing the board which would mean some ugly Frankenstein wires and probably having reliability issues down the road or sacrificing the TI-83 that originally came out of the case...with the screen lines that take 10 seconds to reappear...and the now missing battery panel...yeah, I think I'll be sacrificing the TI-83. I know that board is in pristine condition.

I ended up getting my order of parts for my calculator, which I'm thinking of calling a Hackulator. One of the things I ordered was a mini HDMI port extender so I can hook it up to a monitor without taking apart the calculator and without having all of the ports exposed (though it is still an option at this point). I took all of the boards and the battery and I was able to fit them inside the case. After a little bit of moving items around inside, I'm pretty sure I know where I want all of the boards. For the new display board, I am able to fit it right behind the LCD display, so the extension cable is no longer necessary. Also, it feels like it weighs just a little less than a real TI calculator with batteries.

I looked at the new display board and made note of all of the pins it uses in a spreadsheet and then I did the same for the audio board I got. It turns out that the audio board and the backlight want to use the same pin, so I cut a little trace that's meant to be cut on the display board. I still have the option of using a different PWM pin (GPIO13) if I want to resolder the and hook it up to a different wire. That would leave 15 free GPIO pins if I still use GPIO13 for PWM. The calculator keyboard has 50 keys arranged approximately in a 5x10 fashion so that works out.

The only thing I'm not sure about yet is that for my power board I may need to use an additional GPIO for power control which means no backlight control. Another option is to multiplex the keyboard so that I can send voltage using only 3 GPIOs for the columns instead of 5 freeing up a pin. The downside is that it would require additional circuitry and I don't have much space inside the case.

I already modified the new display board. I successfully desoldered the 2x13 connector from the board and placed electrical tape over that spot so there wouldn't be any accidental shorts. I started modifying the case as well and was able to fit the audio connector right next to the display, which ended up being a bit of a challenge. I still need to enlarge the display window and cut out the HDMI port on the bottom. Once everything is done, if it turns out like I plan, there shouldn't be any issues placing the slide cover on the calculator.

I went and soldered the wires running from the raspberry pi to the new display and at first it wasn't working and I realized it used a split ground plane, so I soldered a second ground wire for the other half. I'm still having an issue where it only works sometimes. I think I have narrowed it down to FBCP because even if it starts up and it's not displaying what's on screen, I'm able to run some programs that output to it just fine. Also the touchscreen is working fine too.

The next step is to continue modifying the case so that everything fits inside. At the same time I need to get the new display board working consistently. I looked and it appears somebody has already written a driver for making use of a matrix keypad, so that should make this that much easier. My goal is to have this completely working by the time I go to the hackaday convention so I can bring it with me. In all likelihood, I think I could get this finished in the next month so that shouldn't be a problem.

It's worked! Once. I checked all of the connections and everything seemed to checkout fine. I booted it up and it did the same thing as it did yesterday with the black screen. So I figured it wouldn't hurt to try running the script again. It must need to probe something for the settings or my messing around with it may have messed something up, but it started working. As luck would have it, the very stiff HDMI cable I was using lifted the entire setup into the air and the LCD panel fell off. I attached it back on, but I still haven't been able to get it working. I switched to a regular HDMI cable, but I've only been able to get the top quarter inch of the display to work. I'm looking into an alternate solution. I have a resistive display that is exhibiting the same symptoms when plugged in so I think it's the board I'm having issues with.

While it was working with the touchscreen and all, I noticed that attempting to use a capacitive screen did not allow me to click on small things. I'm thinking about switching to a resistive LCD and possibly having the arrow keys control the cursor. I placed an order for an Adafruit PiTFT 2.4" HAT Mini Kit - 320x240 TFT Touchscreen. The advantages to this are that I believe it will work with an existing Resistive Touch LCD that I already have, that it doesn't come with buttons or headers soldered on so there won't be anything to destroy, and because it's designed for a smaller LCD, it's already a smaller sized board.

The next steps are to try booting it with the extension cable, but I don't think that will be an issue and then starting work on making the calculator keyboard working. I'm thinking I'll read them as some kind of matrix and since the buttons have a resistive value, I'm thinking I'll check the resistance to make sure it's not routing a button press through 3 buttons.

I didn't have much time to work on it today, but I did discover one of the wires I used for repairing was attached to the wrong point. I moved it to the correct place and although the screen did initialize (changed from white to black), it didn't display properly. I still need to check that the connections are proper and that there aren't any other shorts in my soldering job. If that checks out, I can try running the init script for the display, but I don't suspect that will do anything. It could be a similar issue as well on another wire.

I am so close now with getting the LCD working with the Pi Zero. I got the desoldering tools in the mail, so I went ahead and desoldered the parts I wanted and cut the board down. Unfortunately while doing so, I broke off a few pads. So the next step was looking at a schematic and figuring out which connections needed to be connected between the Pi and the LCD. I meticulously added wire and did repairs on it and tested each with a multimeter and then soldered wire between the Pi and the LCD.

I then went ahead and downloaded a more recent version of Raspbian and installed it on an SD card, hooked the Pi up to my TV and finished the install. I ran a script from Adafruit to set up displaying the output to the LCD and rebooted. It was black. I realized I forgot a ground wire and added that, but still no connection. I removed the LCD extension cable and plugged the LCD directly in the board and it was white. I fiddled with the extension cable and finally got everything the correct side so now the LCD is displaying white. I booted up again and it goes from white to black (but still illuminated) during the process, so that's where I'm at. I also double checked all connections from the raspberry pi to connection points on the board and everything checked out fine and the touchscreen moves the mouse, so it's definitely only the display portion not working.

On another note, it was announced that the Hackaday Super Conference tickets, so I went ahead and snagged an early bird ticket since hardware hacking is one of my favorite activities. Speaking of which, I think I'm going to change the name of this section due to it being more generalized. Probably electronics or maybe hardware hacking or something else if I think of something better. Robotics was just a little too narrow.

I have made a bunch of progress. First I'll start with the calculator project. I received the PowerBoost and the battery in the mail, so that allows me to know how well stuff will fit. I started desoldering the connections on the LCD board, but that was soldered way too well, so I ordered a solder sucker and that should help with removing the main connector. I then took the insides of the TI-83 and placed them into the TI-86 case which was kind of a fun project in itself. It involved a little cutting, drilling, and soldering, but in the end it functions well. The only thing is that the labels on the buttons don't match up to the actual functionality of the buttons.

I then took the TI-83 Plus case and removed a lot of the excess plastic so I could fit everything inside. I realized there's no audio jack on the raspberry pi zero, but building a small circuit should be doable. I also need to figure out exactly how I want the power on/off to work with the raspberry pi since it will be in a calculator form. Ideally I would like the ON button for the calculator to take it out of a halt state and for it to put it in a halt state if pushed when the shift key is pressed so it functions like the calculator on/off button.

On a different project, I had previously assembled a DSO038 Oscilloscope kit and wasn't able to get it to function properly. Apparently I had missed a step and didn't remove a wire that wasn't supposed to be in there. Removing it restored the functionality, so now I have another completed project as well as another tool.

Well, for now I'm giving up on my 3D printer and moving onto a new project. After the new project is finished, I may circle back to the 3D printer. The new project involves putting a Raspberry Pi Zero W and LCD into a TI Calculator case and getting the buttons to function as a keyboard. I will also be adding a Lithium Ion battery so that the whole thing is rechargeable.

This is something I've had on the back shelf since December or so when I got the idea. In the mean time I've acquired a couple of TI calculators and the Raspberry Pi Zero W. I also got an extension cable and have been planning how everything will fit in the case. Yesterday I took apart a TI-86 that was non-functional and used a heat fun to remove all of the components from the board. I plan on using a TI-83 Plus for the case because I think it looks a little better and it doesn't have the clear plastic that would go on top of the LCD so I could still use the touchscreen. I'm considering the option of mounting the LCD flush so that it's easier to touch the edges, but I'm not set on that..

I went ahead and ordered a Adafruit PowerBoost 1000 Charger to handle the charging of the battery as well as a battery that should fit where the AAA batteries go. Once I have that, I should have everything I need to complete the project. The next steps are to clean up any remaining solder on the circuit board from the calculator and start mapping out the key matrix.. I'm using an Adafruit PiTFT Plus Capacitive Touchscreen and separating the LCD from the circuit board. The reason for the separation is that the circuit board makes it too big to fit in the calculator case. I may also end up cutting the board down as well as desoldering the buttons and larger connector and soldering the raspberry pi directly to that board. I may also end up soldering a ribbon cable between the board if that would make them too thick. I'm also hoping to be able to fit the PowerBoost where the button cell battery would normally go, but I'll know more once I receive everything,

At this point I need to get everything working together electrically, then I'll get it to fit in the case and finally I also need to work on the software. I'm hoping to find some information about reading the keys and placing the key presses directly into the input stream.

Today I went and tried out a few new settings. I changed the numbers so that the dimensions were a lot more accurate. Then I went and even though the extrusion rate was too much, I increased it further because it didn't seem like it was flowing together nicely. For another cube, I increased the printing temperature and it seemed to bond together better. I have a suspicion that it's reading the temperature wrong and so I may need to further increase the temp. Regarding the motor slipping on the X-Axis, I realized that was one of the motors I had not upgraded yet, so that may be one of the things I do soon so I can avoid any more layer shifting, especially since I already have the motor.

I started working on a Bill of Materials. The problem I was finding with the I3 was there were quite a few variations. I believe I have narrowed it down to the MK2S version and I need to come up with a BOM for that. I selected that one because it seems to be a good balance between ease of parts acquisition and sturdiness/features of the printer.

In regards to my current printer, I remembered something about removing a diode if you wanted to power it externally, so I did a little digging. There's a diode on the RAMPS board that if removed, requires the printer to be plugged into a computer. However, the advantage is that the USB power and the main printer power are separated. I decided to go with this since I was pretty paranoid after having the printer blow up the USB port, keyboard, and trackpad of a laptop I had used. While attempting to remove it, it seems I accidentally loosened a capacitor, so I went and pulled out a spare RAMPS board and successfully removed the diode on that.

I went ahead and plugged in the board into the printer and hooked up the wires for the hot end and heated bed and placed the first stepper motor driver into it. Then I played around with plugging various motors in until I had the first axis working correctly. I continued doing this for the other axises and extruder. Then I got the end stops plugged in and finally the temperature sensors. Each time I unplugged the printer between installing stepper motor drivers or plugging in motors so I wouldn't damage anything. I was able to get all of the functions working correctly. I went ahead and adjusted the power screws on the stepper motor drivers. While doing that, I noticed something strange. While I touched a screwdriver to the screw, if the motor was attempting to move, it would play some foreign radio station through the motor.

After everything was set up, I loaded Slic3r and entered my printer settings and decided to print a cube for testing out the dimensions. It went terribly wrong. The infill wasn't printing very good. I slowed the printing down for the inside and increased the heat. I then tried again and it was a bit better, but failed mid-print because it shifted over a few millimeters. I increased the power to the X-Axis since that was the axis it slipped on. I still have a few more things I want to try such as different filament and slowing down the speed. If that doesn't work, I may try a one of my newer how ends. It appears I can take the bowden tube holder out and it should fit right in. However, it's a little taller, so I would have less print area height-wise.

I want to make sure I can print off the printer parts for the I3 before I spend any money on the hardware, so this will be my focus. I'm quite certain I can do it if I adjust enough things.

So I went to check if I had the latest firmware and I see they now have documented the process of setting of the configuration. So I downloaded the firmware, went through step by step and finished the settings. I was able to get it to compile and upload it to the 3D printer.